Applicable Industries:

Manufacturing Plant, Construction worksÂ

Showroom Location:

None

Condition:

New

Type:

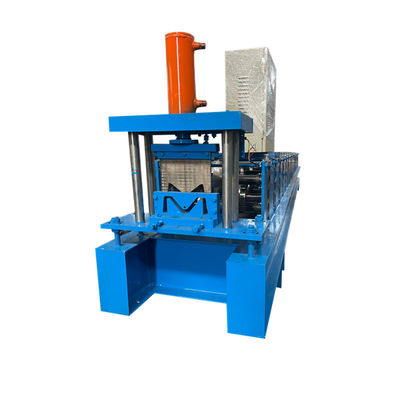

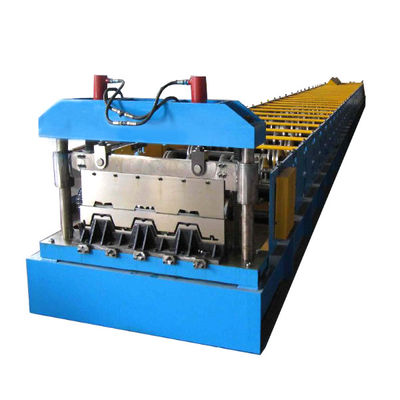

Tile Forming Machine

Tile Type:

Colored Steel

Use:

ROOF

Production Capacity:

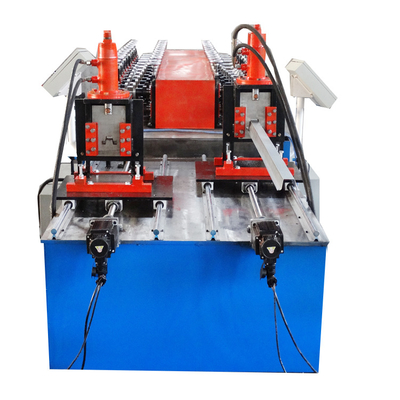

10--18 m/min

Voltage:

380 v or custom

Dimension(L*W*H):

6700mm*1550mm*1200mm

Weight:

About tons 3.5

Warranty:

1 Year

Key Selling Points:

Easy to Operate

Rolling thinckness:

0.3-0.8mm

Feeding width:

915mm

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Marketing Type:

New Product 2020

Warranty of core components:

1 Year

Core Components:

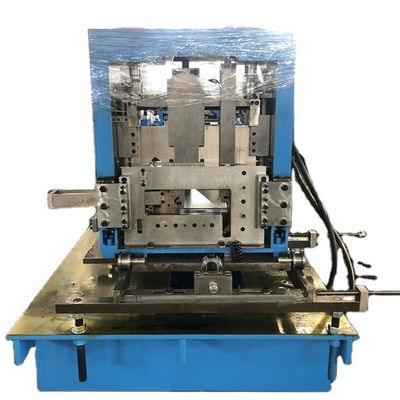

Pressure vessel, Motor, Bearing, Gear, Pump, Gearbox, Engine, PLC

Product name:

Automatic roofing forming Machine

Roller material:

45#steel Chrome Plated

Cutting blade material:

Cr 12 High Grade Steel

Shaft material:

High Grade No.45 Forged

Control system:

PLC(imported Brand)

Thickness:

0.3--0.8mm

Material of rollers:

45# Cr Plated

Color:

Client's Request

Suitable material:

Color Galvanizedsteel Coil

Cutting type:

Hydraulic Cutting

After Warranty Service:

Video technical support, Online support

Local Service Location:

None

After-sales Service Provided:

Online support, Video technical support

Certificación:

CE/ISO

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!